MINE MACHINE

CHALLENGES SOLVED.

Geographe partners with Global Miners and Offsite Repairers who value innovative approaches to mining equipment parts and machine maintenance. We work with you to reduce safety risks, improve machine uptime, and lower operating costs.

We achieve this through Enhanced Performance wear parts, Specialised Tooling and Asset Optimisation of your mining machinery.

Global Miners Benefiting from Enhanced Performance Wear Parts & Specialised Tooling Include:

Discover Geographe Mining Equipment Products

Parts to keep your fleet moving

Geographe has designed and manufactured OEM replacement parts for leading heavy mobile mining equipment brands to suit a diverse range of surface mining machines since 1968.

Learn about our partsRaising the standard of aftermarket wear parts

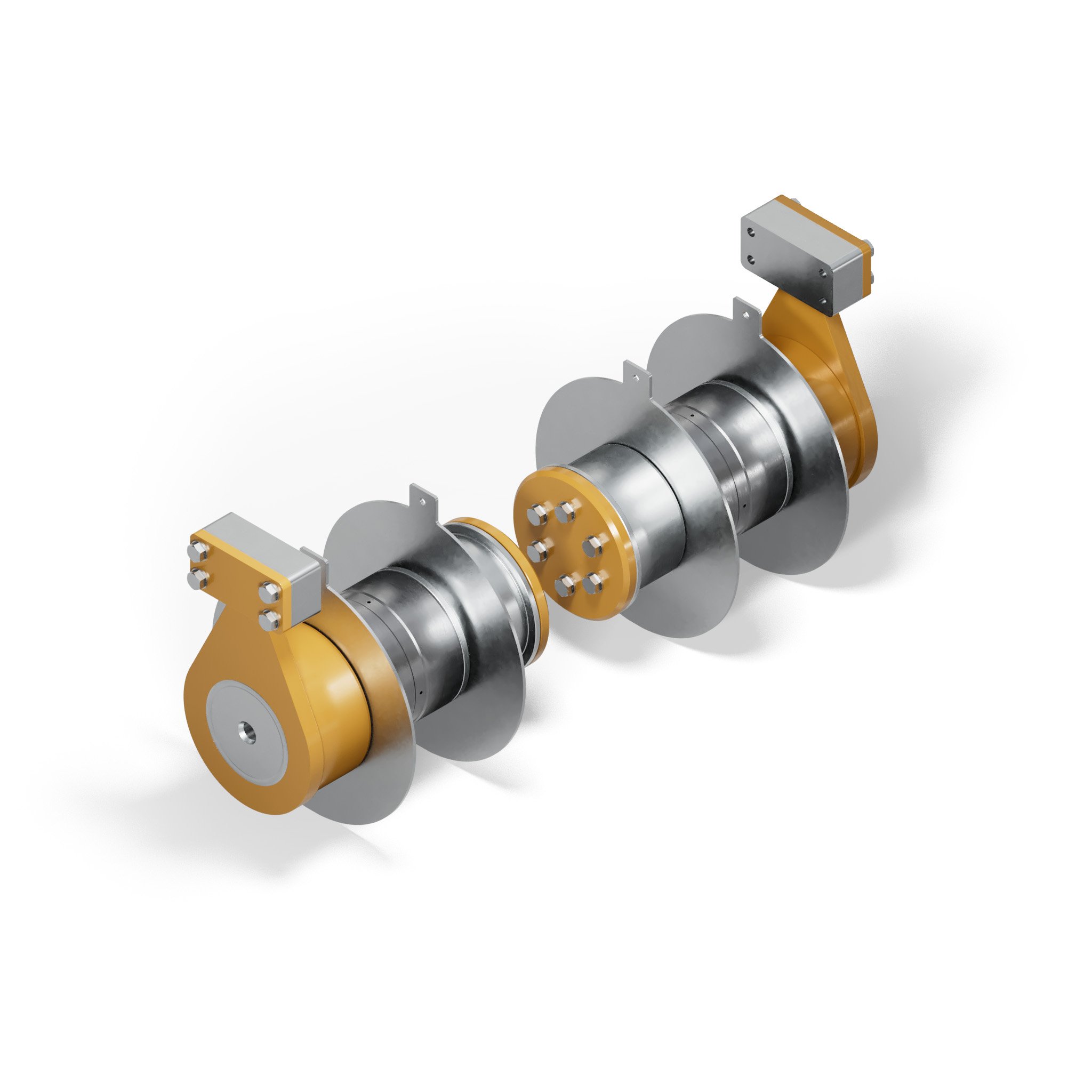

We've been improving HME wear parts since the 1970's. In 1994, we added Enhanced Performance (EP) as a parts category to address common challenges found in heavy machinery equipment used in mining operations. EP parts are designed to increase safer working practises, fleet productivity, durability and reliability on machines from major OEM's including Caterpillar, Komatsu, Hitachi & Liebherr.

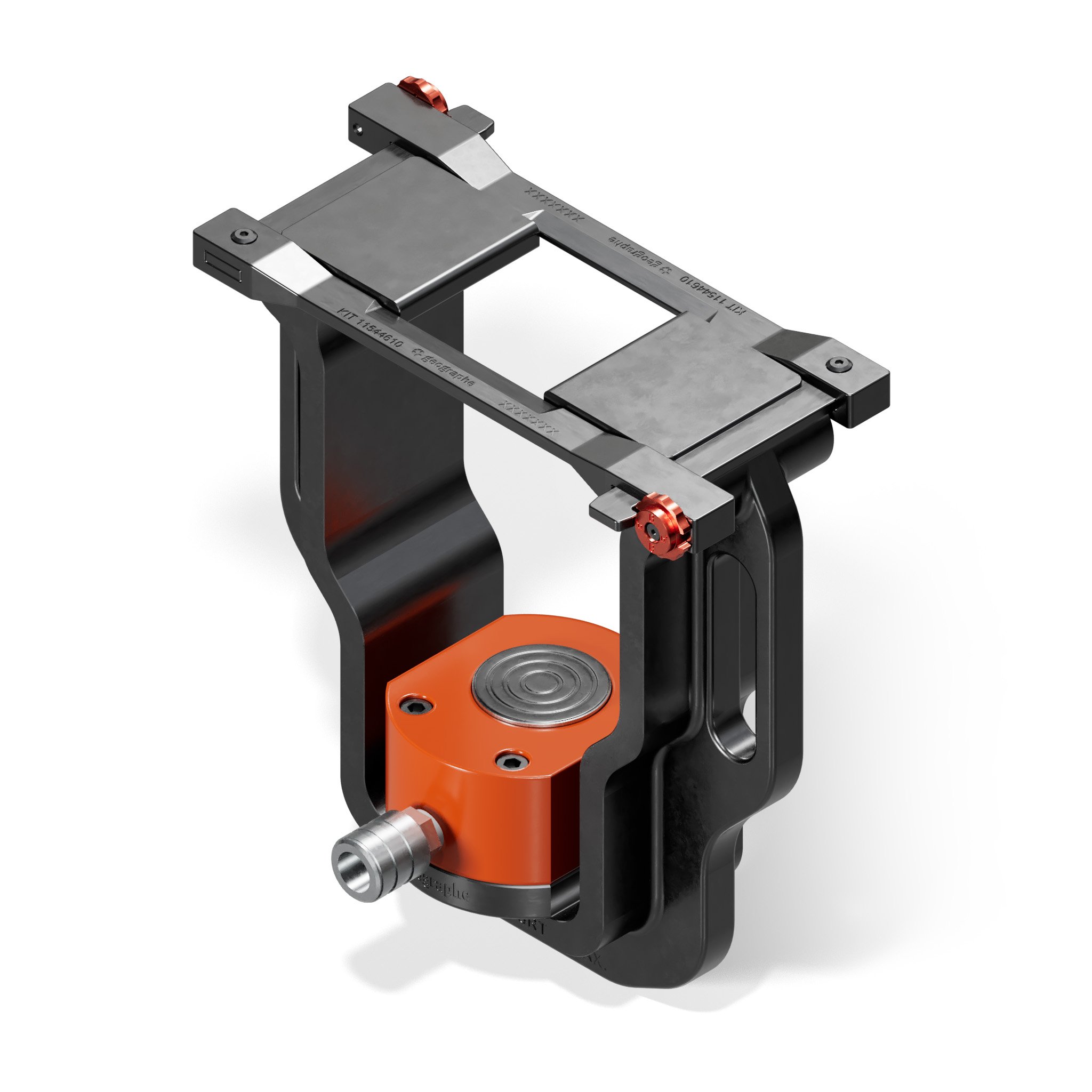

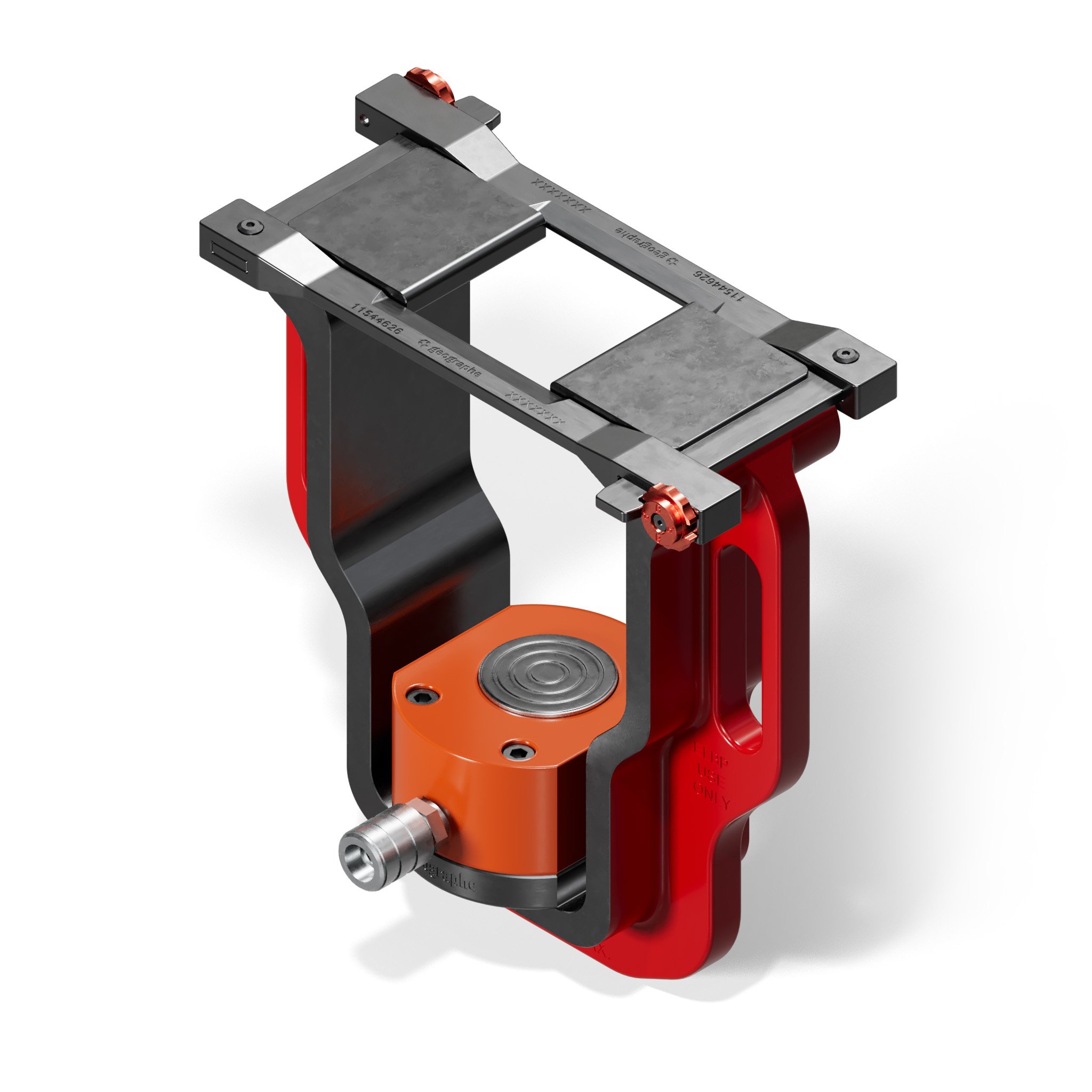

Reduce risks associated with machine maintenance

Our innovative specialised tooling solutions are designed with core purpose of improving safety for workers and reducing the time it takes to install and remove mining equipment components.

With you for the long haul

Partnering with Geographe allows us to work with you to achieve the best solutions for your fleet. We help miners globally to reach their business goals and attain optimal site performance.

Through quality Replacement Parts, Enhanced Performance Parts (EP) and Specialised Tooling, we can support you with keeping your workforce safe during equipment maintenance and optimising your machine assets for maximum uptime and lifespan.

Reduce operational risks & maximise business outcomes

We solve your equipment

challenges

Our Enhanced Performance (EP) Parts are designed and engineered in Western Australia to address global site challenges, from extending asset life to reducing maintenance costs, improving serviceability and increasing uptime.

Superior quality mining equipment solutions

At Geographe, we empower our customers to improve their equipment through innovation. We partner with you to design bespoke solutions that help deliver safer working environments, optimal equipment performance and reliable improvements that help contribute to mine site profitability.

Proven experience solving customer challenges

We've proudly collaborated with every Tier 1 Miner in Australia, and many others globally. For almost six decades, Geographe have supplied miners and offsite repairers with high-quality parts and tooling engineered to go the distance.

Local manufacturing for prompt turnaround

Geographe are your trusted design and manufacturing partners for mining success. We support global miners with Enhanced Performance parts to improve fleet performance, ensuring your mine stays at its peak performance. Our manufacturing presence spans Australia, Africa, China, Malaysia and Mexico to ensure we can cover supply where you require it.

Our people thrive in an environment of innovation and collaboration

We value diversity, inclusiveness, collaboration and growth which we instil in our working life, culture and operations. We invest in our team creating career development and learning opportunities for the long-term.

FEATURED

The Role of Enhanced Performance Parts in Safer Mining Equipment Maintenance

Mining equipment maintenance has long been a challenge due to the demanding conditions and heavy workloads that accelerate wear and tear. While traditional methods such as thermal lancing have been effective, they come with significant risks. However, the emergence of Enhanced Performance (EP) Parts it offers a safer and more efficient solution for maintenance practices.

FEATURED

The High Demand for Quality Wear Parts

Geographe supports mining customers by optimising their mobile fleet to minimise operational costs through Geographe Enhanced Performance™ (EP) parts and solutions. Geographe’s EP parts have also been instrumental in preventing premature equipment failure in North-East Asia, particularly the top hat bush, a custom solution engineered to enhance the original product design and strength of the thrust plate and bush arrangement in Hitachi excavators.

FEATURED

Ball Stud Removal Tool Puts Geographe on the Map

After the Geographe team received a call from the workshop of a Tier 1 miner regarding a maintenance challenge on a common haul truck, the West Australian manufacturer turned a major safety issue into a patented, time-saving tool.

.png?width=759&height=960&name=AM%20December%202021%20cover%20(1).png)

Working and mentorship at Geographe

Working and mentorship at Geographe

Apprenticeship programs

Apprenticeship programs

Expressions of interest

Expressions of interest

Career opportunities and available jobs

Career opportunities and available jobs